Diversified Applications of Silicone Rubber in the New Energy Vehicle Sector

2025-08-18

As an important alternative to traditional fuel-powered vehicles, new energy vehicles (NEVs) have garnered widespread attention and achieved rapid development worldwide in recent years. Their main categories include battery electric vehicles (BEVs), plug-in hybrid electric vehicles (PHEVs), and fuel cell electric vehicles (FCEVs). With technological advancements, NEVs have made significant progress in market share, technological innovation, and industrial chain development, with sales hitting new highs consistently.

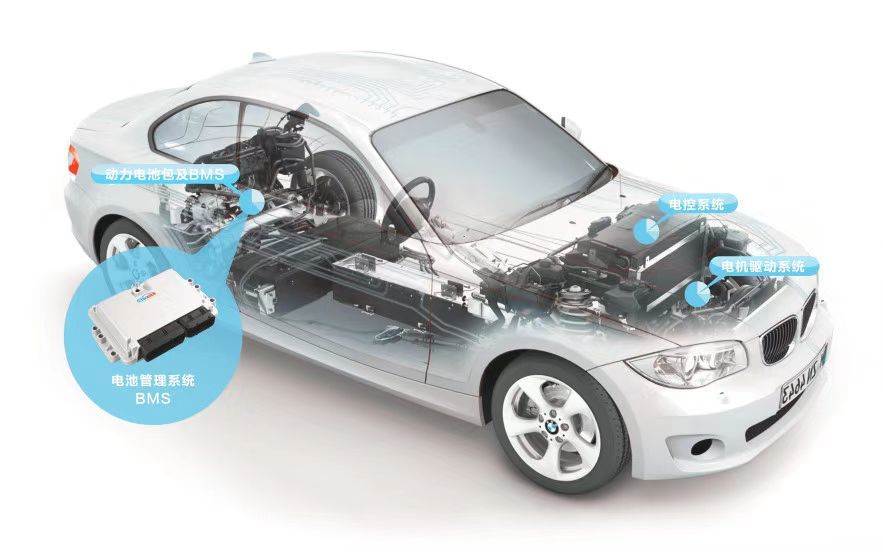

Silicone rubber can maintain stable physical properties within an extreme temperature range, typically from -55°C to +300°C. Therefore, it is particularly suitable for use in battery management systems (BMS), motors, and other automotive components that need to operate in high or low-temperature environments. Additionally, silicone rubber exhibits excellent electrical insulation performance, making it ideal for motor insulation and wire protection in electric vehicles. It also has inherent resistance to many chemicals, including common oils, solvents, and acidic substances. This chemical stability is especially crucial for battery packaging and electrical connection components, as they often come into contact with potentially corrosive substances.

Silicone rubber has a wide range of applications in NEVs. For instance, it plays a vital role in battery management systems (BMS), where it is commonly used to manufacture insulating gaskets and seals between battery cells. Owing to its good thermal insulation performance, silicone rubber can serve as a thermal insulation layer between battery cells, reducing heat transfer among cells and helping maintain the overall temperature balance of the battery pack. Moreover, its excellent chemical stability and temperature resistance make it suitable for use as a sealing material for battery cells—it can prevent electrolyte leakage and protect battery cells from external environmental factors such as temperature fluctuations and chemical erosion. In terms of charging port interfaces, silicone rubber is often used to make sealing rings and gaskets for charging ports, which can effectively prevent moisture, dust, and other contaminants from entering the charging interface, reducing corrosion or damage caused by environmental factors. These sealing rings and gaskets also prevent electrical leakage during charging, ensuring the safety of the charging process. Furthermore, silicone rubber can be used to produce waterproof and dustproof covers for charging interfaces; these covers shield the interface when not in use, preventing potential damage caused by external factors and extending the interface’s service life.

The popularity of touchscreen technology has led to the gradual integration of touchscreen controls for some functions in NEVs. However, physical buttons still remain necessary. Physical buttons are mainly made of plastic, silicone, and P+R (Plastic + Rubber) materials. They provide bounded physical feedback, making them more suitable for enabling fast and accurate operation execution while driving. Meanwhile, they are more durable and entail lower maintenance costs. NEVs are equipped with physical buttons in multiple locations:The inner side of the car door is usually fitted with buttons for controlling window lifting, adjusting exterior rearview mirrors, and locking the door.

Below the instrument panel or hidden under the steering wheel, some vehicles are equipped with buttons for adjusting driving modes (e.g., eco mode, sport mode) and activating the vehicle stability control system.

If the vehicle is equipped with a sunroof, the button for controlling the sunroof (opening/closing) is typically located on the roof near the center console.In some NEVs with seat heating or steering wheel heating functions, the relevant control buttons are usually placed beside the seats or on the center console, facilitating use by drivers and passengers in cold weather.

Recommend News