The difference between precipitated silica and fumed silica

2025-01-06

The two main product forms of silica with filler as the main application form are: precipitated silica and gas phase silica. Because the most important difference lies in the production process and its raw materials, the final product is different in structure, form, element composition, etc.

One of the most important downstream application areas is silicone rubber, according to the different application scenarios of silicone rubber products and the selection of different structures, forms, elemental components of silicon dioxide products, in order to achieve the best performance and cost performance required for final use.

Figure 1. Appearance of precipitated silica (left) and gas phase silica (right)

Precipitated silica

Precipitated silica is mainly prepared by wet method, and inorganic acids such as sulfuric acid, hydrochloric acid and CO2 are used to react with water glass (sodium silicate) to precipitate silica out, and then the product is obtained through filtration, washing, drying and other steps. This method has mature technology and relatively low cost.

It is mainly used in rubber tires (as a reinforcing agent of natural rubber and synthetic rubber to significantly improve the wear resistance, tear resistance and aging resistance of rubber), coatings and paints (as a matting agent, thickener and anti-deposition agent to improve the suspension stability and thixotropy of coatings), toothpaste (as a friction agent to help remove dirt and plaque on the surface of teeth).

Fumed silica

Fumed silica is the use of organosilicon, polysilicon production process of intermediate products halosilane (such as silicon tetrachloride, methyl trichlorosilane, etc.) in the hydrogen-oxygen flame hydrolysis at high temperature to produce fine, special amorphous silica products. It has different characteristics from precipitated silica, such as small particle size, uniform particle size distribution, large specific surface area, spatial network structure, and high surface adsorption activity.

Widely used in the field of silicone rubber (room temperature glue and high temperature glue to strengthen, adjust the flow, processing, etc.), paint and paint (increase the viscosity, hardness and durability of the system, and as an anti-caking agent and anti-precipitation agent), sealant adhesives (improve the bonding strength, prevent the flow during the fixed line), cosmetics (used as oil absorbent, sunscreen and thickening agent, etc.) Improve the transparency and texture of cosmetics).

The difference and its impact on material properties

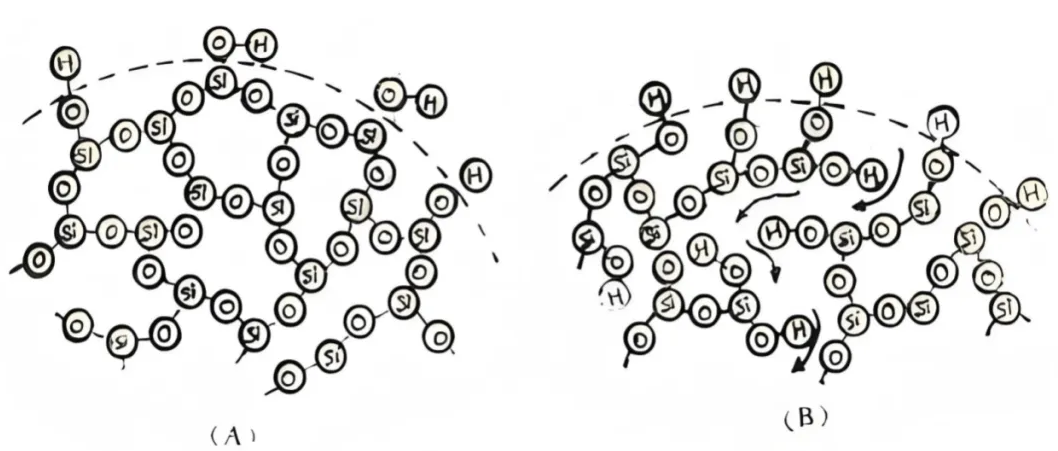

The microstructure of precipitated silica usually presents an irregular binary linear structure, and the internal arrangement is looser plane configuration than that of fumed silica, so it forms a capillary structure from a chain two-dimensional structure. The existence of this structure makes the precipitated silica have a higher oil absorption value and a certain hydrophilicity.

The fumed silica, because it is generated from sufficient space reactor, has a primary nano-spherical structure, and free space movement results in a three-dimensional skeleton structure with tight internal arrangement. There are three forms of primary particles, secondary particles and aggregated particles in the formation process, among which the primary particles are initially formed spherical, and the forces formed by the adsorbed hydroxyl group on the surface interact to form chain dendritic secondary particles, which then adhere to each other and form an dispersed aggregated state.

Make reasonable use of its differences

The difference between precipitated silica and gaseous silica is that:

1. Spatial structure, fumed silica has a three-dimensional spatial network structure, which has better enhancement, rheological control and filling effect;

2. Particle size, select powder with different particle sizes for different resin systems and processing equipment;

3. Particle size morphology, spherical fumed silica has smaller filling gap and better reinforcement effect;

4. Elemental composition, the content of other elements of fumed silica can be maintained stable and pure by process equipment;

5. Hydroxyl content, the hydroxyl content of generally precipitated silicon dioxide is as many as dozens per square nanometer, while fumed silicon dioxide is in several.

In the actual use process, the different requirements of the application should be made.

Recommend News