Application and Innovative Development of Liquid Silicone Rubber in New Energy Vehicles

2025-07-02

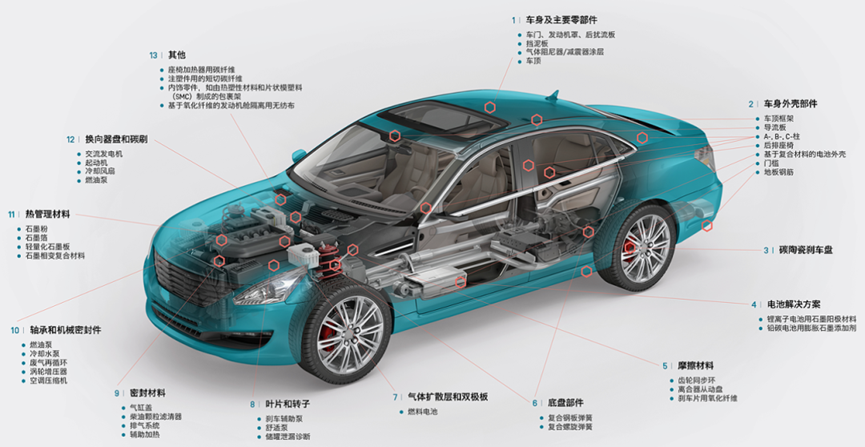

Liquid Silicone Rubber (LSR) has become a core material in the new energy vehicle (NEV) sector, thanks to its high temperature resistance, chemical corrosion resistance, excellent sealing performance, and precision molding capabilities. It plays an irreplaceable role in key components such as battery systems, motor controllers, and thermal management systems.

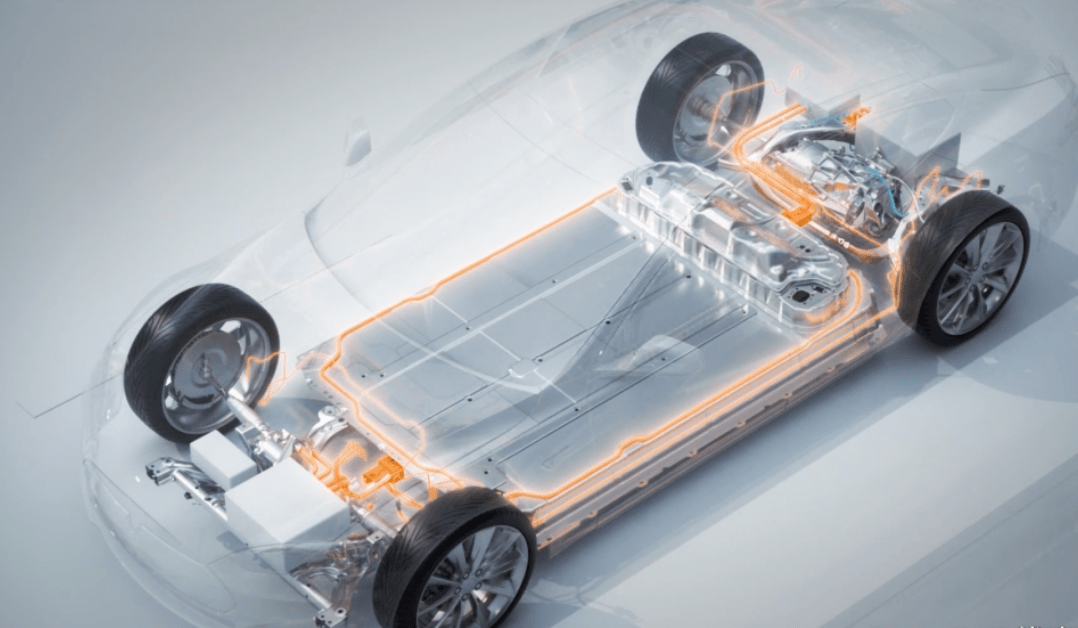

I. Battery Systems: Dual Protection for Safety and Performance

1. Battery Pack Sealing and Protection

- Multi-layer Sealing for IP68 Compliance: LSR provides multi-layer sealing structures for battery modules through injection molding, meeting IP68 protection standards to prevent moisture and dust intrusion and resist electrolyte corrosion. For example, Tesla’s 4680 battery pack uses LSR gaskets for high-reliability sealing, while in-line foamed silicone (e.g., Wacker ELASTOSIL® LR 38xx series) is used for shock absorption protection of pouch cells, absorbing vibration impacts during vehicle operation.

- Fire Retardancy: Ceramicizable silicone coatings (e.g., new Wacker silicone rubbers) form a high-temperature-resistant ceramic layer (withstanding over 1000°C) during battery thermal runaway, effectively preventing fire spread and significantly enhancing vehicle safety.

2. Thermal Management and Heat Conduction

- Thermal Conductive Gap Fillers: Wacker SEMICOSIL® 96xx TC series thermal conductive silicone rubbers connect battery modules to cooling systems, enabling rapid heat dissipation and maintaining stability from -45°C to +180°C. They are also compatible with automated coating processes.

- Lightweight Design: By adding fillers such as glass microspheres, LSR maintains high thermal conductivity (e.g., 0.88W/m·K) while reducing density, optimizing battery pack energy density.

3. Electrical Insulation and Safety

LSR’s high dielectric strength (>25kV/mm) and low dielectric loss properties isolate battery busbars from metal enclosures, preventing short circuits and surge risks. It also meets insulation requirements for high-voltage wiring harnesses (800V systems).

II. Motor and Electronic Control Systems: Precision Protection and Efficient Operation

1. Motor Sealing and Insulation

- End Sealing and Winding Fixation: LSR seals motor ends and outlet ports to prevent lubricant intrusion. As a winding potting material, its low-stress curing property protects precision magnet wires from vibration damage, enhancing motor reliability.

- Temperature Resistance: Addition-cured LSR operates long-term at -60°C to 200°C, adapting to high temperatures generated by high-speed motor operation.

2. Electronic Control Module Protection

Chips and circuit boards in Battery Management Systems (BMS) and motor controllers are potted with LSR for moisture, dust, and impact protection. For example, Wacker ELASTOSIL® RT 76xx TC series fully immerses electronic components, maintaining stable performance under complex operating conditions.

III. Thermal Management Systems: Precise Temperature Control and Long-Term Sealing

1. Cooling Pipe Sealing

LSR O-rings and gaskets connect battery cooling pipes, with ethylene glycol coolant resistance and high elasticity ensuring no leakage under temperature fluctuations from -40°C to 150°C.

2. Thermal Interface Materials

Highly thermally conductive LSR (e.g., SEMICOSIL® Paste 40 TC) fills gaps between heating elements and heat sinks, replacing traditional silicone grease for more efficient heat conduction (thermal conductivity >1.5W/m·K) while avoiding drying and failure.

IV. Charging Systems: Safe Connection and Durability

1. Charging Pile Interface Sealing

LSR is used in charging gun heads and on-board charging ports, with wear resistance (>10,000 insertion/extraction cycles) and arc resistance (>10kV voltage resistance) ensuring charging safety. For example, Molex ML-XT series connectors use integrated LSR molding to achieve IP68 protection.

2. High-Voltage Harness Protection

Oil-permeable LSR (e.g., Wacker ELASTOSIL® LR 38xx) forms a lubricating layer on harness gasket surfaces, facilitating automated assembly. It maintains low compression set from -55°C to +210°C, preventing loosening of high-voltage harness interfaces.

V. Fuel Cell and Hydrogen Energy Systems: Corrosion Resistance and Sealing Innovation

1. Fuel Cell Stack Sealing

LSR’s low hydrogen permeability (<0.1cm³/(m·h·bar)) and chemical stability make it suitable for bipolar plate sealing in Proton Exchange Membrane Fuel Cells (PEMFC), replacing traditional rubber to extend service life.

2. Hydrogen Storage Equipment Sealing

Valve seals for 70MPa high-pressure hydrogen storage cylinders use perfluoroether-modified LSR, withstanding hydrogen embrittlement from -40°C to +150°C and meeting ISO 15869 standards.

VI. Innovation Directions in Intelligence and Lightweight

1. Smart Seals

LSR seals embedded with flexible sensors monitor real-time pressure and temperature changes in battery packs, combined with AI algorithms to thermal runaway risks. For example, a car manufacturer’s self-sensing seals achieve ±1% pressure detection accuracy.

2. Multi-Material Co-Injection Technology

LSR and engineering plastics (e.g., PA66) are co-injected to manufacture integrated components. For instance, the battery pack end plate of a BYD model uses an LSR-metal composite structure, reducing weight by 20% while improving impact resistance.

3. Bio-Based and Recyclable Materials

Companies like Dow have developed bio-based LSR (containing 30% renewable raw materials) for interior parts, while detachable sealing designs (e.g., Tesla battery packs) facilitate battery recycling and reduce environmental impact.

VII. Typical Cases and Technical Parameters

Application Scenario | Material Characteristics | Representative Products / Technologies | Performance Indicators |

|---|---|---|---|

Battery pack sealing | Electrolyte resistance, IP68 protection | Wacker ELASTOSIL® LR 3025 | Compression set < 5% (150°C × 22h) |

Motor winding potting | Low stress, high insulation | Shin-Etsu KE-1310 | Dielectric strength > 30kV/mm, hardness 30A |

Thermal interface materials | High thermal conductivity, flowable | Wacker SEMICOSIL® 96xx TC | Thermal conductivity 1.8W/m·K, viscosity < 5000cps |

Fuel cell sealing | Low hydrogen permeability, chemical resistance | 3M™ 5523TC | Hydrogen permeability < 0.05cm³/(m·h·bar) |

Liquid silicone rubber applications in new energy vehicles have expanded from basic sealing to intelligence and light weighting. Its performance improvements and process innovations (e.g., 3D printing, self-healing materials) are driving the industry toward higher safety and longer service life. Future advancements in solid-state batteries and 800V high-voltage platforms will focus on LSR’s stability in extreme environments (e.g., elasticity at -100°C) and rapid curing processes (e.g., UV-curable LSR).

Recommend News