Ceramic low smoke halogen-free polyolefin refractory

Product description

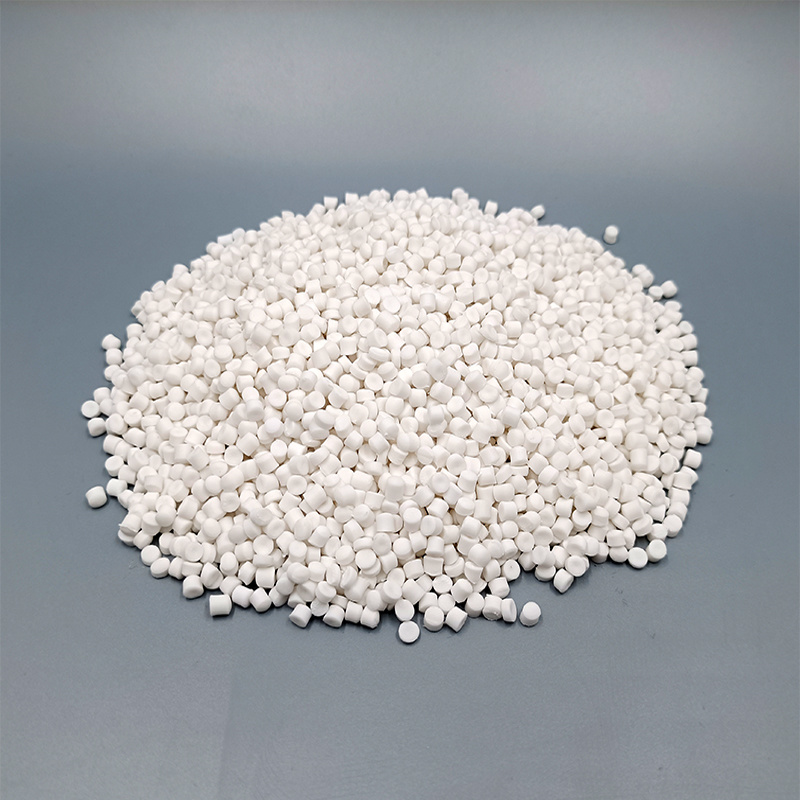

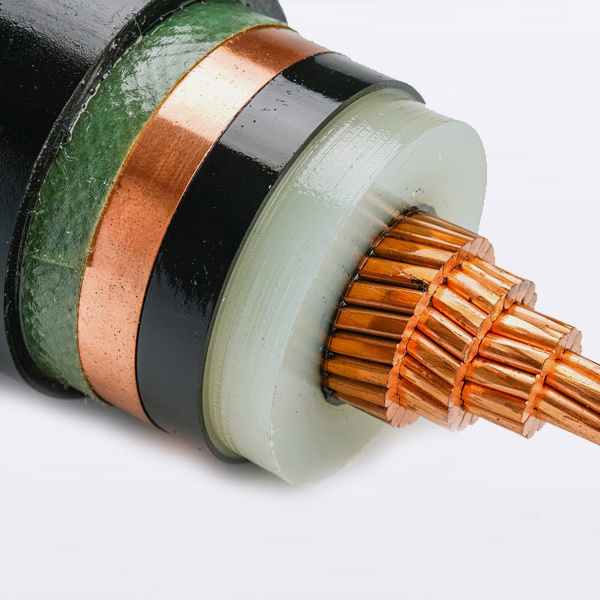

Ceramic low smoke halogen-free polyolefin refractory is a new type of high performance refractory material developed for fire-resistant wire and cable. It takes polyolefin resin as the base material, adds high-efficiency porcelain filler, flame retardant and other functional additives, and is made by mixing, plasticizing and granulating. Compared with the traditional low smoke halogen-free material, its advantages are: in the flame burning or high temperature conditions can generate a hard ceramic shell, the shell does not melt, does not drip, can resist water spray, and has a very good heat insulation effect, can ensure the smooth flow of power and information control in the case of fire, for personnel escape and fire rescue for valuable time.

Product characteristics

● Excellent mechanical and electrical properties

Dielectric strength at room temperature ≥ 20KV/mm, volume resistivity ≥ 1.0 × 1013 Ω.cm, with the same level of hardness, wear resistance and tear resistance as low-smoke halogen-free cable materials;

● Excellent encrusts into porcelain performance

At temperatures above 650°C or under flame conditions, a complete ceramic shell can be quickly produced.

● Excellent fire resistance and thermal insulation

The ceramic shell does not crack or drip. In addition to excellent electrical isolation performance, it also has excellent oxygen insulation and heat insulation effect, which can effectively isolate the infringement of high temperature flame on the inside of the line, delay the decomposition of the inside of the material, avoid the fuse of the conductor in the flame, and ensure the smooth flow of the line in case of fire;

● Excellent economy and processability

Using ordinary polyolefin cable material processing equipment, a molding, simple process, continuous production, lower production costs;

● High fire resistance rating

The fire resistance rating of fire-resistant cables produced by ceramic low-smoke halogen-free polyolefin refractory materials can pass the following standard requirements:

(1) Class A standard of GB/T12666.6

(2)IEC 60331 standard

(3)GA 306.2 standard

● Excellent safety and environmental protection

Low smoke halogen-free, non-heavy metal, non-toxic and tasteless, in line with RoHS standards;

● Wide scope of application

It can replace ordinary oxygen barrier material and sheath material;

Main application

Medium and low voltage fire-resistant cables, flexible fire-resistant cables, fire-resistant power and control cables, mining cables, ship cables, etc.

Typical product data

| Test Items | Test Method | LSP335 |

| Specific gravity (g/cm3) ≤ | ASTM D1505 | 1.55 |

| Tensile strength (MPa) ≥ | IEC 60811 | 8.5 |

| Elongation at break (%) ≥ | IEC60811 | 400 |

| Volume resistivity (Ω.cm) ≥ | IEC 60093 | 1012 |

| Dielectric strength (MV/m) ≥ | IEC 60243 | 18 |

| Melt index (g/10min) | GB/T 3628-2000 | 1 |

Processing equipment and processing technology

Use ordinary polyolefin wire and cable extruder, processing temperature 160-170 ℃.

| Location | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Zone 5 | nose |

| Temperature ℃ | 150-160 | 150-160 | 160-170 | 160-170 | 160-170 | 165-170 |

Safety and storage

* Polyolefin should not be exposed to the sun and rain during transportation.

* Store in dry and cool warehouse, avoid direct sunlight.

* Place out of reach of children.

Packing

* 25KG bag lined with plastic. Kraft paper composite bag packaging.

Key words:

Ceramifiable Polyolefin

Previous Page

More products

Contact Us

Building 1, No. 23, Chashan Weixing Road, Chashan Town, Dongguan City, Guangdong Province, China

Tel: +86-769-82786088

Mobile: +86-18098293536

E-mail: wmdsb@longsunkeji.com

Follow Us

Copyright © 2024 Dongguan Longsun Material Technology Co.,Ltd

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.