product manual

Ceramic low-smoke halogen-free polyolefin refractory is a new type of high-performance refractory developed for fire-resistant wires and cables. It is made of polyolefin resin as base material, adding high-efficiency ceramic filler, flame retardant and other functional additives, through mixing, plasticizing and granulating. Compared with the traditional low-smoke halogen-free material, its advantages are: it can produce a hard ceramic-like crust under flame burning or high temperature conditions, the crust does not melt, does not drip, can resist water spray, and has a very Good heat and fire insulation effect can ensure the smooth flow of power and information control in case of fire, and buy precious time for personnel escape and fire rescue.

Product Features

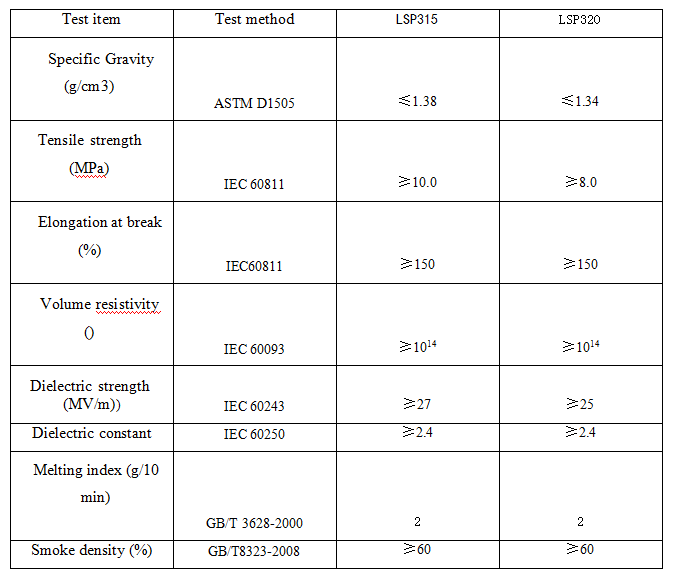

●Excellent mechanical and electrical properties

At room temperature, the dielectric strength is ≥25KV/mm, and the volume resistivity is ≥1.0×1014Ω.cm. It has the same level of hardness as the low-smoke halogen-free cable material.

Wear resistance and tear resistance;

●Excellent crust-forming properties

Under the temperature or flame conditions above 650℃, a complete ceramic shell can be quickly formed, and the bending strength can reach 10MPa;

●Excellent fire resistance and heat insulation

The resulting ceramic shell does not crack or drip. In addition to its excellent electrical isolation performance, it also has an excellent oxygen and heat insulation effect, which can effectively isolate the high temperature flame from the internal damage of the circuit, delay the internal decomposition of the material, and avoid The conductor is fused in the flame to ensure the smooth flow of the circuit in the event of a fire;

●Superior economy and processability

Using ordinary polyolefin cable material processing equipment, one-time molding, simple process, continuous production, compared with ceramic silicone rubber, no need for two

Secondary heating or steam vulcanization, energy consumption is smaller, process operation is simpler, and production cost is lower;

●Excellent safety and environmental protection

Low smoke, no halogen, no heavy metals, non-toxic and tasteless, in line with RoHS standard requirements;

●Wide range of application

It can replace ordinary oxygen barrier materials, sheath materials and ceramic silicon rubber products;

main application

Medium and low voltage fire-resistant cables, flexible fire-resistant cables, fire-resistant power and control cables, mining cables, ships and ships, etc.

Typical product dat

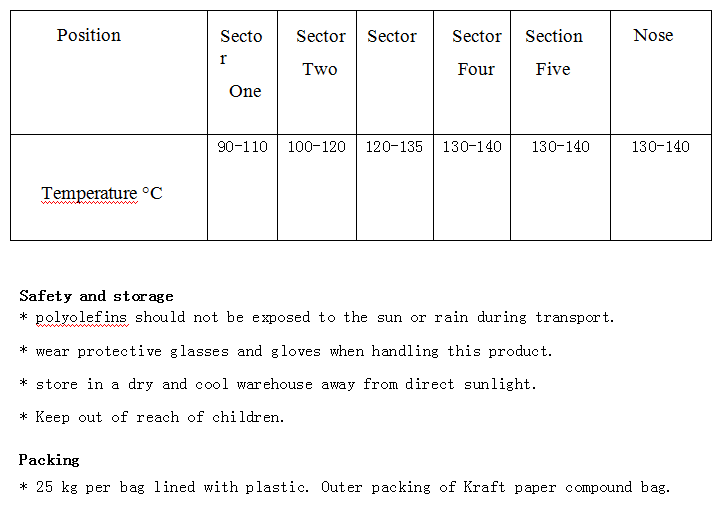

Processing equipment and processing technology

Using common polyolefin wire and cable extruder, processing temperature 130-140 °C.